Effective Microorganisms for your home

Enjoy colourful flowers and fruits full of flavour from your own garden. By using Effective Microorganisms, you can create a healthy environment in the soil and on leaf surfaces. This makes your plants less prone to attacks from pests and diseases. In your pond, Multikraft technology keeps the water crystal clear and improves water quality. You can also use Effective Microorganisms in a variety of ways in your home.

What are Effective Microorganisms? Effective mechanism

Sustainability

Natur im Garten (natural gardening)

Multikraft is a proud partner of the “Natur im Garten” (natural gardening) movement. The initiative, whose membership now includes more than 15,000 garden owners, promotes gardening without artificial fertilisers, pesticides or peat.

This extensive network has set itself the task of raising awareness of natural gardening among the general public. This makes us all the more pleased that a range of Multikraft products have been awarded the “Natur im Garten” seal of quality.

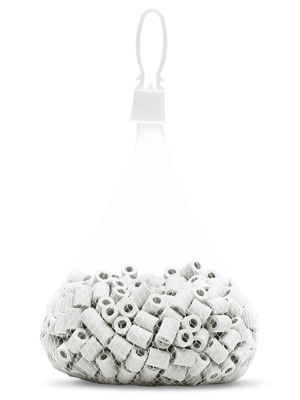

Bestsellers for home, garden and pond

Future events

Blog

The latest news from the world of home, garden and pond

With the right care, plant strengthening and balanced fertilisation, ideal conditions are created for healthy, robust plants – without the use of harmful chemicals. We show the difference between plant strengthening and fertilisation and the advantages they offer compared to the use of pesticides.

In a world in which more and more people are looking for sustainability and environmentally friendly products, it is no wonder that demand for natural cleaning products is growing. The new Multikraft cleaners offer exactly that: an innovative, probiotic cleaning solution that not only cleans thoroughly, but also has a lasting effect and leaves a long-lasting freshness. But what makes these cleaners so special?